Stainless Steel

Mammalian Cell Culture Bioreactor

25 Years Experience Bioreactor/Fermenter Manufacturer

Your Reliable Chinese Cell Culture Bioreactor Manufacturer : Ferbio

Ferbio is a leading bioreactor manufacturer in China.Ferbio produces various types of biological fermenters, capable of producing bioreactors with volumes ranging from 0.1L to 1000KL, and provides technical services to provide intelligent and personalized comprehensive solutions for bioreactor processes. The products provided by Ferbio are classified by scale, there are seed fermenters, pilot scale bioreactors, and industrial scale bioreactors; In terms of usage, there are vaccine bioreactors, cell culture bioreactors, bacterial bioreactors, plant cell bioreactors, etc. In addition, Ferbio also has supporting equipment for bioreactors, such as air compressors, chillers, steam generators, centrifuges, etc. Ferbio has a large team of experienced fermentation process, biochemical equipment, and chemical technology engineers, with many renowned experts and scholars serving as technical consultants for the company. Ferbio always puts customer needs first and insists on putting customers at the center.

Stainless steel Mammalian Cell Culture Bioreactor

The Mammalian Cell Stainless Steel Bioreactor is a high-performance bioprocess system designed for large-scale cultivation of fragile mammalian cells, such as CHO, HEK293, NS0, hybridoma, stem cells, and CAR-T cells. Built from pharmaceutical-grade 316L stainless steel, this bioreactor delivers industry-leading sterility, durability, and process control — making it an ideal solution for biopharmaceutical production, vaccine development, cell therapy manufacturing, and clinical-grade biologics.

Engineered to support both batch and perfusion cell culture, this bioreactor is optimized for high cell viability, gentle mixing, and precise control of environmental conditions. It integrates seamlessly into GMP-compliant manufacturing environments and supports scalable production from pilot to full-scale volumes.

Key Features & Advantages

1. GMP-Grade Stainless Steel Construction

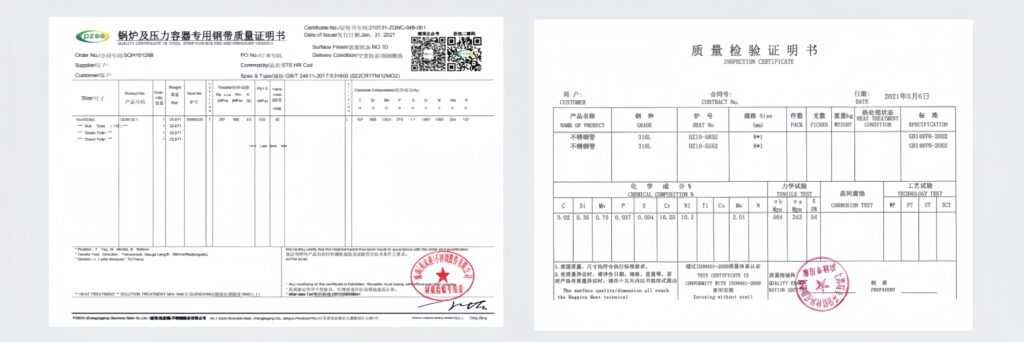

Vessel made from 316L stainless steel with internal surface roughness ≤ 0.4 µm (electropolished).

Complies with ASME ,GMP manufacturing standards.

2. Low-Shear Agitation System for Fragile Cell Lines

Gentle mechanical or magnetic stirring system designed to maintain high cell viability and productivity.

Various impeller options available (pitched blade, marine, elephant ear) to accommodate suspension or microcarrier cultures.

Top-drive or bottom-drive agitator with variable-speed control for customizable mixing.

3. Precise Environmental Control

Fully automated control of temperature, pH, dissolved oxygen (DO), agitation, antifoam, and pressure.

Advanced PLC control systems with touch panel.

Supports multi-stage control recipes for cell growth, production, and harvesting phases.

4. Multiple Gas Control Strategies

Independent mass flow controllers (MFCs) for air, O₂, N₂, CO₂ for accurate gas mixing.

5. Seamless Cleaning and Sterilization

Full CIP/SIP capability for inline cleaning and sterilization with minimal downtime.

All contact surfaces are fully drainable and slope-designed for zero dead-leg zones.

Validation ports for temperature mapping, SIP cycle verification, and process qualification.

Cases

30L cell culture bioreactor with chiller and steam generator BLBIO-SCUC

150L cell culture bioreactor BLBIO-SCUC

500L cell culture bioreactor BLBIO-SCUC

Know More About Stainless Steel Cell Culture Bioreactor

| Parameter | Description |

| Total volume | 5L~10KL |

| Working volume | 30%~70% |

| Tank | Inside electrolytic polishing, precision: 0.2-0.4um. Diameter and height ratio 1:1.5 |

| Stirring system | Magnetic drive, low shear mixing blades. Stir speed: 30~300rpm |

| Sterilization | Sterilize in place (SIP), auto control by program |

| Clean | Clean in place by spray ball |

| Gas control | Provision for mixing at least four gases (Air, Oxygen, Nitrogen and CO2) Auto control by mass flow meter. Air flow 1vvm, O2/N2/CO2 0.1vvm. |

| Feeding | Automatically feeding by peristaltic pump |

| Anti-foam control | Automatically add antifoamer by peristaltic pump |

| Temperature control | Auto-control, electric heating range: water source add 5℃ to 70℃ |

| PH control | PH 2.00-12.00±0.1, auto-control adding acid/base by peristaltic pump, pH sensor from Hamilton/Mettler, Switzerland. |

| Do control | 0-150±3% displaying precision 0.1%, DO sensor from Hamilton/Mettler, Switzerland. DO coupling with agitation, oxygen. |

| Sampling valve | Can sterilization separately, manual |

| Harvest | Zero dead zone bottom valve, can sterilization separately, manual |

| Weight system | Mettler-Toledo, Switzerland |

| Pressure | Auto control, BD Germany pressure transmitter or Lambert differential pressure liquid level gauge. |

| Exhaust | Have condenser before exhaust, control by diagram valve / Proportional control valve. |

| Control parameters | 10 or 15 inch touch screen, Siemens PLC with control parameters (stirring, pH, DO, temperature, feeding, alarm, gas etc.), data analysis, data record, data output, language(RU/EN/CN) and other customized functions |

| Optional configuration | We can customize the parameters of cell culture bioreactor according to customer needs,such as Remote control, Mass flow meter(auto control gas), exhaust heating, exhaust filter, gas(CO2) exhaust analysis, Level sensor, Turbidity(OD) sensor, ORP sensor, Weight system, Live cell sensor(Biomass), Printing, Siemens touch screen, Double mechanical seal, 4-valves-group for feeding, Bottom valve auto, ASME certificate, CSA certificate, air flow 2vvm, etc. |

Supporting Equipment

The refrigeration system of a chiller unit consists of four basic parts: compressor, condenser, throttle, and evaporator. Connect the four major components in a certain order using copper pipes to form a closed system, which is filled with a certain amount of refrigerant.

The compressor sucks in low-temperature and low-pressure Freon gas from the evaporator, compresses it into high-temperature and high-pressure Freon gas, and then flows through a thermal expansion valve (capillary tube), throttling it into a low-temperature and low-pressure Freon liquid two-phase object. Then, the low-temperature and low-pressure Freon liquid absorbs heat from indoor air in the evaporator, and the cycle of compression condensation throttling evaporation is repeated.

The Bailun steam generator uses well-known imported accessories, which are corrosion-resistant and finely crafted. Fast steam production in one minute, with a thermal efficiency of up to 100.27%. Clean steam, sufficient gas production, can provide stable steam for a long time, ensuring the required heat energy during the drying process. Advanced vertical cross flow structure, using 12Cr1MoVG high-pressure boiler steel and stainless steel laser fins with extremely high heat transfer efficiency, no explosion risk, safer equipment, and better steam quality.

Bailun air compressor is an oil-free and silent air compressor equipped with a domestically produced powerful air pump and a gas tank with built-in anti-corrosion coating. It has a high cost performance and is used as a supporting equipment for bioreactors. Has the following characteristics:

● Independently produce machine heads and components;

The machine is equipped with multiple automatic protection systems for safer use;

● Easy to operate, ready to use upon power connection, automated design, no need for dedicated personnel to operate the work;

●Low noise during work, original oil-free piston system, high efficiency, low loss, and clean gas discharge;

●Optional double-layer vacuum drying and filtering equipment to meet the supply of high-purity air source and protect user equipment;

Related Products

Send Inquiry

Our Advantages

Extensive Manufacturing Experience

With over 20 years of bioreactor production expertise, our factory delivers high-performance systems trusted by global biotech and pharmaceutical companies.

Customized Solutions

We provide tailor-made bioreactor designs to meet diverse application needs, including microbial fermentation, cell culture, and pilot-scale production. ers with a full range of solutions.

Full Range of Products

From lab-scale glass fermenters to industrial stainless steel systems, we offer a complete portfolio to support all stages of bioprocess development.

Global Technical Support

Our experienced engineering and after-sales teams provide responsive service and on-site support worldwide.