Clean in place (CIP system) are widely used in food and beverage production enterprises with a high degree of mechanization, such as beverages, dairy products, juices, pulp, jams, and wines. The method of using chemical agents to remove dirt from the surface of an object is to chemically transform, dissolve, and peel off the surface pollutants or covering layers of the cleaning agent to achieve the effects of degreasing, rust removal, and decontamination.

Under certain flow/pressure conditions, the cleaning agent solution is sprayed or sprayed onto the surface of the equipment or circulated in the equipment. The entire cleaning process usually consists of multiple independent cleaning steps.

1.Classification and characteristics of Clean in place (CIP systems)

According to the use method of cleaning liquid, it is divided into CIP system with single use of cleaning agent, CIP system with repeated use of cleaning agent, and CIP system with repeated use of cleaning agent.

The CIP system with single use of cleaning agent is a system in which the cleaning liquid is only used once and there is no large-capacity diluent storage tank. It is composed of CIP tank, CIP pump, reflux pump, concentrated cleaning agent pump, heat exchanger and pipeline, forming a loop with the device to be cleaned. After the cleaning is completed, the cleaning liquid is directly discharged and no longer recycled.

The acid and alkali cleaning liquid in the CIP system with repeated use of cleaning agent can be reused. Its water, alkali, acid and other cleaning liquids are placed in their respective storage tanks. After the cleaning is completed, the acid and alkali cleaning liquids are recovered for recycling.

The cleaning liquid of the CIP system with repeated use of cleaning agent is centrally provided by the storage tank. After the cleaning is completed, the cleaning liquid can be recovered for reuse. The CIP system with repeated use of cleaning liquid combines the characteristics of single-use CIP system and repeated use CIP system.

The overall Clean in place (CIP system) has the following characteristics:

(1) The Clean in place (CIP) systems can ensure absolute cleaning effect, thereby improving the quality and safety of production products;

(2) The Clean in place (CIP) systems can save operation time and labor, save energy such as water vapor, ensure equipment operation safety, and improve work efficiency;

(3) The Clean in place (CIP) systems can realize the large-scale production equipment, improve the automation level of production equipment, and extend its service life.

2.Composition of CIP cleaning unit

High-pressure cleaning pump

The high-pressure cleaning pump is an indispensable and important part of the entire CIP cleaning unit, mainly including high-pressure water pipes, water inlets, cleaning agent nozzles, power cords, temperature control switches, power switches, high-pressure pump assemblies, motors, etc. In practical applications, the water jet generated by the high-pressure cleaning pump can quickly break and remove the scale by flushing, wedge splitting, shearing, grinding and other composite crushing effects on the inner wall of the equipment.

Cleaning spray ball

The cleaning spray ball is installed in the container to be cleaned, and the cleaning liquid is sprayed from the nozzle of the nozzle to rinse the container. The cleaning ball is divided into thick-walled standard cleaning ball, rotating cleaning ball, vortex cleaning ball and intense jet cleaning ball according to the form.

Thick-walled standard cleaning ball has the characteristics of low energy consumption, low maintenance and low flow rate, but the cleaning time is long.

The rotating cleaning ball usually has 2~4 nozzles, and the cleaning pressure can reach 3~5 bar. It is an ideal cleaner for fermentation tanks with a diameter greater than 4.5 m, but rotation failure will cause cleaning failure.

The vortex cleaning ball represents the highest level of current cleaning technology. It can be directly sprayed and cleaned without an ejector.

The intense jet cleaning ball is used to clean stubborn dirt. The internal turbine drive system can provide higher flow rate and pressure to achieve the purpose of strong cleaning.

Electrical control cabinet

The electrical control cabinet is the core of the Clean in place (CIP) system. The electrical control cabinet is mainly composed of touch screen and PLC, inverter, circuit breaker, relay, transmitter and other components to achieve the purpose of monitoring and controlling temperature, conductivity, time, etc. during the cleaning process.

3.Factors affecting CIP cleaning effect

The CIP system achieves cleaning effect through four major factors: kinetic energy, thermal energy, chemical energy and time. The main factors affecting it are the flow rate, temperature, detergent concentration, cleaning time, penetration, water hardness, the number, type, state, thickness of dirt, and the material and plane structure of the equipment.

01 Flow rate

The greater the flow rate of the cleaning liquid, the better the cleaning effect, but the amount of cleaning liquid increases as the flow rate increases, which means that the cost is increasing, so the flow rate should be controlled at about 2 seconds per meter.

02 Temperature

The temperature rise can change the physical properties of dirt and cleaning liquid and thus increase the cleaning rate, but too high a temperature may cause changes in the properties of dirt, increase the bonding force between dirt and the surface of the equipment, and hinder the cleaning process, so the temperature is controlled at about 70°C.

03 Concentration

Each cleaning agent has an optimal concentration. Increasing the concentration of the cleaning solution can promote the chemical interaction between the cleaning solution and the dirt and increase the cleaning effect. However, too high a concentration of the cleaning solution will cause a waste of resources and lead to counter-effects or side effects, such as corrosion, so the concentration of the cleaning agent should be controlled.

04 Time

Generally speaking, the longer the cleaning time, the better the cleaning effect. However, if the time is too long, the production cycle will be extended. Therefore, in order to improve the utilization rate of the equipment and the cleaning effect, the cleaning time needs to be controlled.

05 Water hardness

The higher the water hardness, the worse the cleaning effect. Therefore, a protective agent needs to be added to eliminate the impact of chemical reactions.

06 Pressure

The greater the pressure of the cleaning solution, the greater its impact force and the stronger the cleaning effect. Commonly used jet cleaning is to spray the pressurized cleaning solution through a nozzle, and impact the surface to be cleaned under the impact force and chemical action.

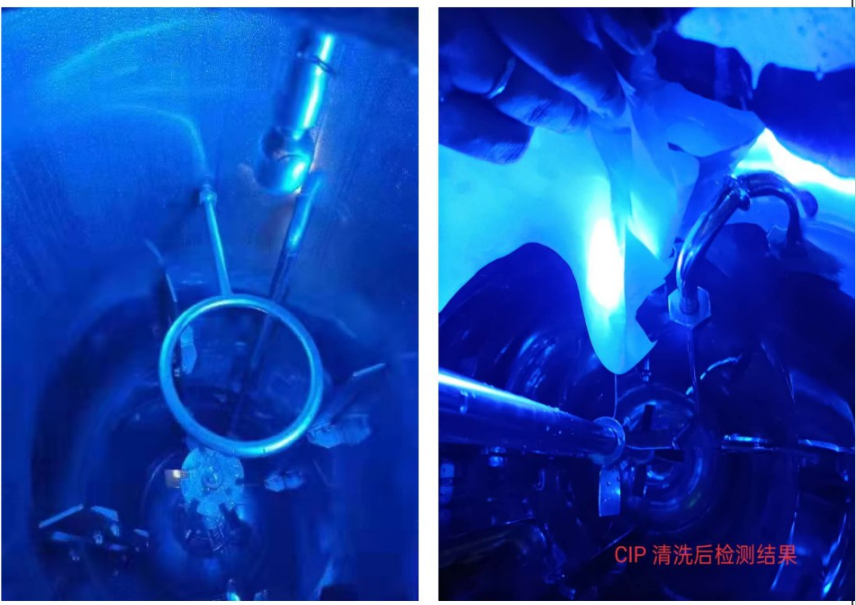

4.Verification of CIP cleaning effect

(1) Fresh smell, no foreign smell. For special processing processes or special stages, a slight smell is allowed but it does not affect the safety and quality of the final product.

(2) The cleaned surface is bright, without water accumulation, film, dirt or other; when water flows over the surface, whether there are too many broken marks of water traces.

(3) When touching the surface with fingers, whether it feels greasy and rough; wipe the surface repeatedly with a new white paper towel to see if there are stains and discoloration

(4) After CIP treatment, the production processing capacity of the equipment has changed significantly.

(5) The microbial indicators of hygiene indicators meet the relevant requirements; it cannot cause the improvement of other hygiene indicators of the product.

5.Bailun clean in space (CIP system)

According to the customer’s cleaning process, Bailun can provide fixed or mobile single tank, double tank or multi-tank structure, and can also choose to configure heating, adding acid, alkaline cleaning agent cleaning and other functions.

Bailun’s clean in place (CIP) system adopts a fully automated cleaning method. Through the human-machine interface graphic display, the formula can be flexibly adjusted to meet the needs of different process production, automatically adjust various related process parameters such as cleaning time, pressure, flow, temperature, etc., automatically prepare different detergent concentrations and automatically detect the CIP cleaning effect. At the same time, all operations can be recorded to facilitate system certification.

Nowadays, with the continuous development of biotechnology, CIP cleaning systems have been widely used in actual production. The functions of CIP cleaning units are becoming more and more comprehensive, and the system operation is more stable, which improves labor production efficiency and corporate competitiveness.

Contact Us:

Add:6848# Liuxiang Rd., Jiading, Shanghai, China

Contact Person: Maddie

Email:sales@fermentertech.com

Phone:+86-134-7276-8163 (WhatsApp)

Website: https://bioreactortech.com/