Selecting the right reactor is essential for increasing cell development, productivity, and yield. Using the correct bioreactor can change your outcomes, whether you are just starting or increasing production. Let’s explore these game-changing reactors to identify your next big discovery.

What are mammalian cell culture reactors?

Mammalian cell culture is an effective method used to produce everything from innovative vaccinations to necessary medications. Unlike bacteria cultures, these cells are more delicate and sophisticated, requiring controlled conditions for them to thrive and function effectively. This is where mammalian cell culture reactors, or bioreactor systems, come in, providing the ideal environment for these cells to grow and contribute to the manufacturing process.

Every type of reactor has unique advantages that make it appropriate for particular uses. But with so many choices ranging from simple stirred tank systems to disposal bioreactors, choosing the appropriate one can be overwhelming. To help you make the best decision for the success of your project, we’ll break down the types and important features.

Common Types of Bioreactors Used in Mammalian Cell Culture

The success of your cell culture directly depends on your choice of bioreactor. Whether you’re working with delicate mammalian cells or trying to optimize protein yield, every form of bioreactor has special benefits that are appropriate for your various applications. Here’s a closer look at each choice and how it can support various mammalian cell culture production objectives.

1. Stirred Tank Reactors (STR)

Stirred tank reactors, or STRs, are the most widely used bioreactors in mammalian cell culture processes. Why? Well, they are quite adaptable. STRs use a mechanical stirrer to continually mix the cell culture media, assisting in the even distribution of nutrients, gasses, and cells throughout the reactor. This mixing also enhances the transfer of oxygen, which is vital for the development and survival of cells, particularly at high densities.

STRs are ideal for producing proteins because of their designs, which frequently call for high-density cultures. Another advantage of their adaptability is that they can easily manage both large-scale commercial production and small, lab-scale activities. Whether you’re improving a process or scaling it out, STRs give the essential control and consistency required to produce excellent outcomes.

2. Wave Bioreactors

Wave bioreactors, also known as rocking bioreactors, are widely used in preliminary research and development. In contrast to STRs, wave bioreactors don’t use mechanical stirring. Instead, they rock back and forth gently creating waves in a culture medium that mixes the ingredients. Such a “wave-like” movement assists in distributing oxygen and nutrients without straining the cells.

Because wave bioreactors are often disposable, they reduce the chances of contamination and eliminate time-consuming cleaning processes. Moreover, they are inexpensive and simple to run, which makes them ideal for process optimization or early phases of cell culture, where you might need versatility without necessarily committing to complex setups.

3. Fixed Bed Reactors

Reactors with fixed beds are made for ongoing cell cultures. They are especially helpful when dealing with vaccinations for viruses or other products that profit from extended culture periods. Cells are immobilized on a solid surface or matrix inside a fixed bed reactor. This design aids the cell to grow and multiply without being washed away during the process, thus ideal for adherent cells that require a solid surface to stick to.

The continuous nature of fixed-bed reactors makes them efficient for processes that need uninterrupted production. By maintaining a steady environment, fixed bed reactors can support long-term cultures, maximizing both yield and productivity over time.

4. Hollow Fiber Bioreactors

One of the distinctive features of hollow fiber bioreactors is their membrane-based mechanism. The setup is based on the arrangement of a bundle of hollow fibers so that diffusion of nutrients and gasses can be regulated. While nutrients pass through the fiber cores and diffuse outward to reach the cells, cells develop in the area outside of these fibers.

This structure allows for very efficient nutrient and oxygen exchange, making hollow fiber bioreactors a popular choice for high-density cultures, especially in applications like antibody and vaccine production. Since the cells remain near the nutrient source, they experience minimal stress and are constantly supplied with everything they need to thrive.

5. Packed Bed Reactors

Packed bed reactors are another type developed for long-term, high-density cell cultures. In this configuration, cells are condensed into a column with immobilized materials such as beads or fibers for their adherence. This arrangement enables cells to multiply in large numbers while remaining stationary. It is perfect for procedures that need to be produced continuously without frequent interruptions.

Packed bed reactors are particularly useful for producing cell-based products over extended periods, as they maintain a stable environment that can support cell growth for weeks or even months. This setup also reduces the need for frequent harvesting, making it efficient for high-output applications.

6. Single-Use Bioreactors

Single-use bioreactors are quickly finding a place in both scientific and industrial applications. As the name suggests, these bioreactors are intended to be used only once, which indicates that thorough cleaning or sterilization is not required. This function streamlines the workflow and drastically lowers the chance of cross-contamination.

Beyond the convenience factor, single-use bioreactors are also highly flexible. They can be adapted to various scales and are ideal for industries that need to switch between different products frequently. Furthermore, their disposable nature makes them a sustainable option for biopharma companies looking to minimize waste and streamline production.

The global single-use bioreactor market was valued at USD 4.1 billion in 2023. From 2024 to 2030, the growth rate of the market is expected to expand at about 17% CAGR.

7. Membrane Stirred Tank Bioreactors

Membrane-stirred tank bioreactor integrates a selective membrane with the advantages of a conventional STR. This membrane keeps cells contained within a certain area while permitting the controlled exchange of nutrients and gasses. This characteristic is more useful for procedures that need precisely regulated nutrients without causing the cells to become unduly concentrated.

By leveraging the mixing power of an STR and the selective exchange of a membrane, these bioreactors are well-suited for applications that require fine-tuned conditions, such as scaling up sensitive cell lines.

8. Airlift Bioreactors

One distinctive feature of airlift bioreactors is that they don’t use mechanical stirring, but air bubbles instead. This approach minimizes shear forces, which are particularly sensitive to damaged mammalian cells. When air is let in at the base of the reactor, it rises and helps drive a convective loop around the medium and the cells.

The design of airlift bioreactors makes them ideal for large-scale production where maintaining cell integrity is essential. Since there are no moving parts in direct contact with the cells, airlift reactors minimize cell damage, making them perfect for sensitive cultures or products that need high viability.

9. Spin Filter Stirred Tank Bioreactors

Incorporated with traditional STRs, spin filter stirred tank bioreactors provide a selective layer of management of nutrients. These reactors use a spin filter to keep the cells isolated in one region while separating them from the nutritional solution and permitting free circulation of the medium. It is a configuration well suited for suspension cells that don’t need a surface to adhere to but still gain from a constant supply of nutrients.

Additionally, this design promotes high-density cultures and allows for extended culture periods without having to remove or replace the cells frequently. Therefore, spin filter STRs are particularly effective in suspension-based processes, where efficient nutrient cycling is crucial for productivity.

10. Bubble Column Bioreactors

Bubble column bioreactors have a relatively simple design. Their procedure depends on rising bubbles to mix the medium and provide oxygen. Therefore, they are easy to upscale for high production volumes, and their low-shear environment is kind to cells. The medium is automatically mixed by the rising bubbles, which distribute oxygen and nutrients without the need for mechanical agitation.

These large-scale bioreactors are useful where an inexpensive, non-mechanical method of blending the medium is required. The lack of mechanical components also makes maintenance and operation easier, contributing to a lower overall cost.

11. Tower Bioreactors

Tower bioreactors are designed with a vertical structure, creating a tall, column-like setup that enhances oxygenation and circulation. The increased height maximizes the contact area for oxygen transfer, which is beneficial for high-density cell cultures where oxygen demand is high.

Due to their vertical design, tower bioreactors can support large volumes without taking up excessive horizontal space. They’re commonly used in large-scale industrial applications where maximizing cell density and efficient oxygenation are top priorities.

12. Fluidized Bed Bioreactors

Fluidized bed bioreactors are built for continuous production, particularly with immobilized cells that attach to small particles within the reactor. In a fluidized bed, these particles are kept in constant motion, allowing nutrients to circulate freely around the cells. This movement supports high-density cultures and ensures that cells have continuous access to fresh nutrients.

The setup is particularly useful for processes that require continuous output over long periods. Fluidized beds are often chosen for their high productivity and minimal manual intervention, making them efficient and reliable for large-scale operations.

Each of these mammalian cell culture reactors has unique advantages suited to different goals, from research to large-scale production. Whether you’re working with sensitive cells that need a low-shear environment or scaling up to meet high demand, there’s a bioreactor type ready to support your vision.

Mammalian Cell Culture Reactors: Scale-Up Considerations

When it comes to scaling up, things can get tricky. Let’s look at what you need to know.

1. Importance of Scale-Up

Scaling up is the bridge between research and commercial production. Small reactors used in research might not always work at a larger scale without adjustments.

Imagine trying to keep thousands of cells alive, productive, and stable across a much larger surface area. A disposable bioreactor might work perfectly in the lab, but the scalability factor means a different setup may be needed.

2. Factors Affecting Scale-Up

Key factors like mixing efficiency, oxygen transfer, and bioreactor geometry play a significant role. Therefore, small adjustments in design can make a big difference when working with a bioreactor system.

3. Strategies for Successful Scale-Up

From adaptive monitoring systems to single-use reactors, scale-up strategies vary widely. Single-use bioreactors, for example, offer flexibility by avoiding complex cleaning protocols, which can be a game-changer. However, for high-volume needs, a reusable reactor might be more cost-effective long term.

Comparison of Reactor Types

When deciding which reactor is right for you, it helps to have a direct comparison. Here’s a snapshot of how some popular reactors compare:

| Reactor Type | Scalability | Contamination Risk | Ease of operation | Typical Applications |

| 1. Stirred Tank | High | Moderate | Medium | Protein Production |

| 2. Wave | Low to medium | Low | High | Early stage research |

| 3. Fixed bed | Medium | Moderate | Medium | Virus based Vaccines |

| 4. Hollow fiber | Medium to high | moderate | high | Antibody production |

| 5. Packed bed | High | Low | Medium | Longterm cell culture |

| 6. Single-use | Medium to high | Low | High | Flexible and disposal setups |

| 7. Membrane stirred tank | Medium | Moderate | Medium | Scalable nutrients exchange |

| 8. Airlift | Low to medium | Moderate | Medium | Sensitive cell types |

| 9. Spin filter stirred tank | Medium | Moderate | Medium | Sensitive cell types |

| 10. Bubble column | High | Low | High | Large-scale simple setups |

| 11. Tower | High | Low | Medium | High-density large cultures |

| 12. Fluidized bed | Medium to high | Moderate | Medium | Continuous production |

Key Considerations in Choosing a Mammalian Cell Culture Reactor

Several factors influence which mammalian cell culture reactors will suit your needs. Cell type, for example, determines if you need a system for suspension or adherent cells. The density you’re aiming for, the production volume, and the material (single-use vs. reusable) also impact your choice. Here are a few guiding points:

- Cell Type: Certain reactors, like fixed bed reactors, work well for cells that need to adhere to a surface, whereas stirred tank reactors are ideal for suspension cells.

- Production Volume: Are you working with small, pilot-scale volumes or moving to large-scale production?

- Material: Disposable bioreactors are easier to handle and help avoid contamination, but for large volumes, reusable stainless-steel systems can be more economical.

Future Trends in Mammalian Cell Culture Reactors

As technology advances, mammalian cell culture reactors are also evolving. First, the push towards single-use bioreactors is growing, largely because they reduce contamination risk and cleanup time. We’re also seeing trends in AI-driven process controls that make real-time adjustments to optimize culture conditions.

Looking ahead, sustainable reactor designs and automated bioreactor systems will make large-scale cell culture even more accessible. Imagine reactors that adapt to changing conditions automatically, ensuring your cells are happy and productive. That’s the future of mammalian cell culture reactors!

Conclusion

Selecting the right mammalian cell culture reactors can make or break your project. With options ranging from simple wave bioreactors to high-tech airlift systems, there’s something to fit every need. Whether you’re scaling up for commercial production or optimizing a small pilot run, the reactor you choose should align with your cell type, production goals, and operational preferences.

With ongoing advances in reactor technology, like disposable bioreactor systems and AI-controlled processes, the future of mammalian cell culture is looking brighter and more efficient than ever.

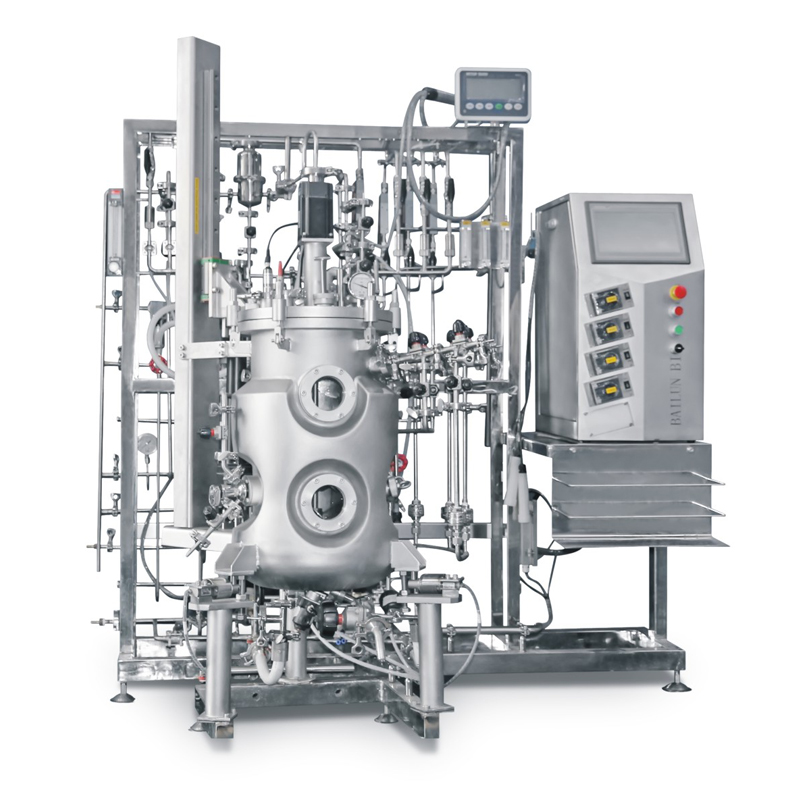

Unlock Precision & Performance in Bioproduction with BaiLun Mammalian Cell Culture Reactors

Ready to take your cell culture processes to the next level? BaiLun’s Mammalian Cell Culture Reactors are engineered to meet the unique demands of mammalian cells, ensuring superior growth conditions, precise control, and scalable performance from lab to full production.

Whether you’re working on groundbreaking research or large-scale biopharma production, our glass and stainless steel bioreactors provide the consistency and efficiency you need for reliable results, every time.

Don’t settle for less in bioproduction—choose BaiLun’s expertise in high-quality, GMP-compliant bioreactors. Explore our range of Mammalian Cell Culture Reactors now and see how we can support your journey to success. Contact us today for a personalized consultation and quote!