How Does a Bioreactor Work? A Comprehensive Guide

Surely, you have once thought how do scientists and engineers grow cells, bacteria, and other microorganisms in a large quantity? It can be used to manufacture life-saving medicines, fuels, or even food, and all of it is accomplished through a bioreactor. So, what does it imply and why is it so significant in the fields of industry?

This article will discuss the fundamental operation of a bioreactor, its various types and how it is different from a biological reactor. We will also explain the types of laboratory bioreactors and their uses in detail in order to equip you with adequate knowledge of this interesting technology.

What Is a bioreactor?

A bioreactor can be described as a container that facilitates growth and provides the necessary conditions required for the biological process to take place. Thus, it provides a favourable setting conducive for microorganism, plant or animal cell growth and ability to perform specific biochemical activities.

Searching for quality bioreactors for your experimentations in your laboratory, company or organization? Come and visit Fermentor China to take a glance at a variety of premium Bioreactors produced for high performances.

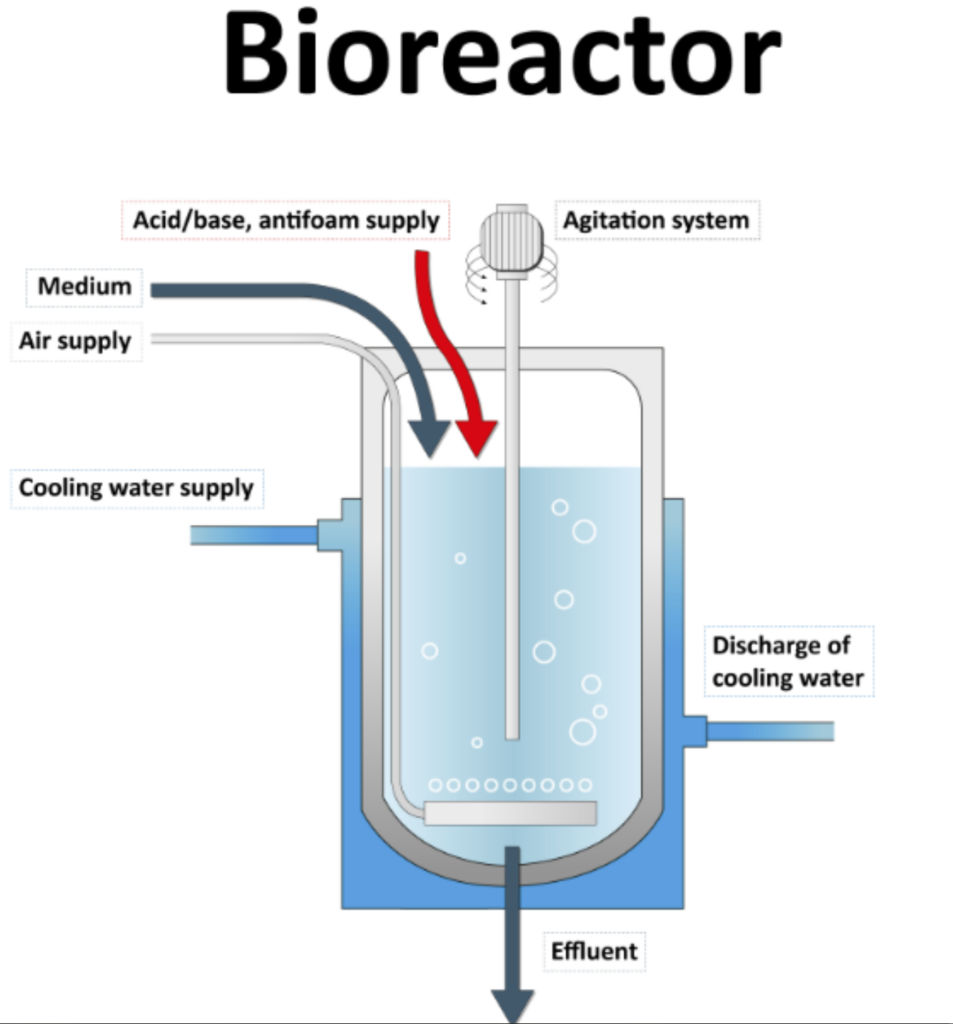

Key Functions of a bioreactor

Here are some of the key functions of a bioreactor:

Temperature Control: Maintaining the optimal temperature for biological activity.

Aeration & Oxygen Supply: Providing sufficient oxygen for aerobic processes.

pH Regulation: Keeping the environment stable for microbial or cell culture growth.

Agitation & Mixing: This is very important in ensuring that nutrients as well as gases needed for the production process are well distributed throughout the production process.

Sterility Maintenance: Preventing contamination from unwanted microbes.

You wouldn’t believe that they will not be able to manufacture industries like pharmaceuticals and even biofuels in the way that it is produced today without bioreactors.

Types of bioreactors

Depending on the purpose they are put to, bioreactors can be classified in one way, or another. There are several types of genetic diseases that exist, let’s describe the most popular ones:

1. Batch bioreactor

This is the easiest type in which the nutrients/microorganisms are introduced first and there is no further contact until the final product is obtained. It is widely utilized in the synthesis of antibiotics, enzymes, and organic acid or in any process where reducing the atmosphere is required. The principle of this system is very easy to operate since there is less control over the growth phases of the organism; hence, it is less efficient than the other types when it comes to mass production.

2. Continuous bioreactor

In this system, a fresh nutrient is provided to the organisms while products are efficiently taken out after a short interval of time, and this makes it suitable for industrial applications. Continuous bioreactors are used widely in the treatment of wastewater, production of biofuel and industrial fermentation and production. While they offer higher productions as compared to batch systems, continuous processes can be best controlled when a steady-state is kept with constant metrics.

3. Fed-Batch bioreactor

A system that combines the constant feeding and the fed-batch system in a manner that results in the elongation of the growth phase and optimization of production. This type of bioreactor is well adopted in pharmaceutical and biotechnology industries for manufacturing high-value products like monoclonal antibodies or recombinant proteins. The slow release of nutrients is also effective in maintaining the metabolic rate of the cells thus improving yield and minimizing toxic substances.

4. Airlift and Stirred-Tank bioreactors

- Airlift bioreactors: They use bubbles to stir their content and therefore one is suited for processes that require a low shear stress like culturing of cells and algae.

- Stirred-Tank bioreactors: Make use of an impeller to create the movement within the tank. These are the most popular bioreactors in the industries due to their versatility and the fact that they allow a homogenized environment for the nutrients and cells in the production process.

It is very important to note that various industries apply distinct categories of bioreactors in accordance with the requirements of the biological processes that are used.

Need a customized bioreactor for your specific application? Fermentor China’ bioreactors offer you the best and latest in bioreactor technology!

How Does a Bioreactor Work?

A bioreactor produces conditions that are best suitable for biological reaction to occur within a short span of time. It covers several stages;

Step 1: Inoculation

The culture system involves putative microorganisms or cells placed on a nutrient medium. This is an important step as the type of strain, media and conditions of inoculation can greatly affect the yield of the final product.

Step 2: Growth Phase

Cells start to divide, active taking up of nutrients and synthesis of the required byproducts occur. It means that growth of bacteria is proportional to nutrient availability, clock, and oxygen level, temperature.

Step 3: Monitoring & Control

Sensors include pH, temperature, dissolved oxygen sensors, and many others to achieve the best results. Positive feedbacks on the other hand, involve the use of feedback to stabilize parameters in the process.

Step 4: Product Formation & Harvesting

When the specific product is attained, it is then separated and purified for use in the next steps. Harvesting can be done through some techniques depending on the type of product to be harvested; Biomass, Extracellular metabolite or intracellular compound.

You would be quite compelled to know that wholescale changes in the percentage of oxygen or the temperature can significantly affect yield.

What Is a Biological reactor, and How Is It Different?

It is important to note that a biological reactor is different or also called a bioreactor though sometimes they are used to refer to the same thing.

Bioreactor: Used for controlled biological reactions in industrial or research applications.

Biological reactor: This term most commonly relates to wastewater treatment where the usage of bacteria to aerobic degrade materials is common.

Thus, even though both of them pertain to biological reactions, a biological reactor is mostly applied for the treatment of environmental and wastewater, whereas a bioreactor concerns industrial processes.

Understanding the Role of a laboratory bioreactor

A laboratory bioreactor is a smaller containment structure used for research purposes in the development of a large scale bioreactor. Today researchers make use of bioreactors in the lab for testing biological processes to be used in large-scale production. These devices help in:

- Testing new pharmaceuticals

- Optimizing fermentation techniques

- Producing small-scale biofuels

It may surprise you but vaccines and antibiotics were first created in a laboratory bioreactor before they were manufactured.

Conclusion

Most people understand a bioreactor as a method that is vital in contemporary science and technology that offers a chance to conduct numerous large-scale biological processes required for medicine, energy, and the environment. Starting from the production of drugs to water purification, bioreactors and biological reactors are now in high demand. If it is a laboratory bioreactor for research purposes or an industrial-scale bioreactor, these systems are changing the way we capture biological power. Therefore, the next time that you pop a pill or utilize a bio- product, you will understand that it all began in a bioreactor!

Do you know which bioreactor technology is the most effective? Contact Fermentor China today and experience the satisfaction that comes with having the ideal equipment to get the job done.

FAQs

- What is the use of a bioreactor?

A bioreactor refers to an apparatus used in the growth of biological activities and the maintenance of optimal procedures for manufacturing of products such as pharmaceutical products, biofuels and the like.

- How does a bioreactor differ from a biological reactor?

A bioreactor on the other hand is one that is used for industrial and research purposes, a biological reactor is mainly used in the waste treatment processes and environmental field.

- What is the significance of a laboratory bioreactor?

A laboratory bioreactor equalizes certain biological processes that need to be tested before they are implemented with the large scale bioreactor.

- Can a bioreactor be used for wastewater treatment?

Yes, some bioreactors are used to treat wastewater, one of which is the anaerobic digester; therefore, it is a biological reactor.

- What industries rely on bioreactors?

Some of the industries that use bioreactors include the pharmaceutical industries, biotechnology industries, food industries and the environmental industries that deal with environmental engineering.