CSTR is used broadly in industries, from biofuels production to developing medicine and cleaning wastewater. It is a force to be reckoned with within industries that require accuracy and efficiency. What sets it apart?

CSTR keeps the right conditions for reactions while functioning continually, saving on time and resources. Because of Its adaptability, it’s a reference in today’s field of fermentation technology. In this article, we will look at the incredible uses of CSTRs in several industries and more. Take a read!

What is a Continuous Stirred Tank Bioreactor?

A Continuous Stirred Tank Bioreactor is a type of bioreactor that is intended to run continuously. Compared to batch or semi-batch systems, a CSTR has a steady state. In this state, the reactor is continuously fed with reactants while products are simultaneously removed.

The key feature? All the reactants in the bioreactor are thoroughly mixed by the ever-rumbling agitation. This ensures that environments are homogenized based on factors like hydrogen ion concentration, heat level, and distribution of nutrients.

Whether you’re working with a stainless steel fermenter used for large-scale production or a single-use bioreactor for R&D, a CSTR offers a degree of regimentation that is impossible with other techniques. This bioreactor is therefore suited to simple chemical reactions as well as more complex biological processes such as fermentation.

How Does a CSTR Work?

A Continuous Stirred Tank Bioreactor’s simplicity is what makes it so brilliant. The reactor has feed ports to supply reactants, an outlet for continuous product removal, and an agitator to promote uniform distribution. The continuous stirring keeps a uniform environment for the reaction, and the situation inside the tank remains similar to that outside the tank.

The question is: Does fermentation use oxygen? That depends on the process. Anaerobic fermentation, such as the synthesis of bioethanol, needs oxygen, whereas anaerobic fermentation, such as the formation of methane, does not require oxygen.

The CSTR is capable of doing both. And, it often includes characteristics such as a sealed system for anaerobic conditions or spargers for the introduction of oxygen.

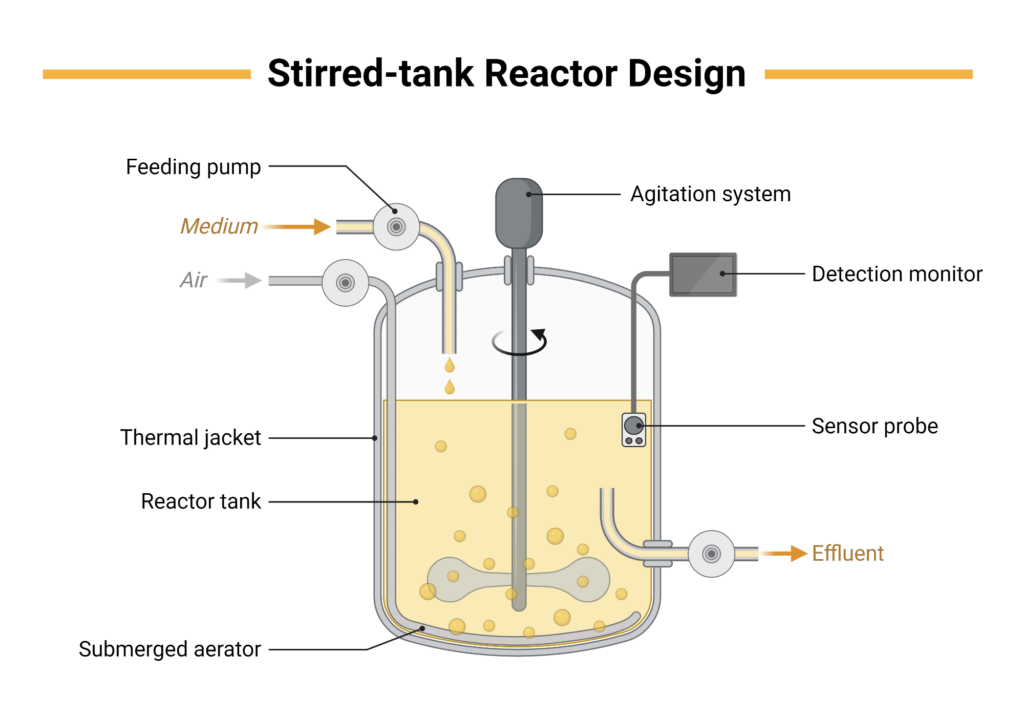

A Peek at the Reactor Setup

While visuals can speak a thousand words, let’s paint a picture of what a Continuous Stirred Tank Bioreactor setup typically looks like:

- Tank: A massive tube in the middle of the reactor, often composed of stainless steel for hygienic and long-lasting reasons.

- Agitator: The mechanism which agitates in order to obtain efficient blending of the contents.

- Input and output ports: Where the discharge of reactants and products are continuously fed and removed.

- Sensors and controls: Instruments to track heat levels, acidity levels, and flow measurements for better control.

Why It Matters

Because of its steady-state flow, homogenous mixing, and controlled residence time, the CSTR is one of the most dependable and effective reactors for both biological and industrial operations. From the transformation of impurities within the wastage stream to the synthesis of essential drugs that can help save lives, the operational principles of a Continuous Stirred Tank Bioreactor guarantee effectiveness.

Let’s take a closer look at how its working ideas translate into real-world situations.

Uses of CSTRs Across Industries

The CSTR fermenter applications are broad and numerous, spanning industries and enabling vital functions in daily life. Be it developing fine chemicals or generating renewable energy, the continuous and homogeneous reaction of the CSTR is irreplaceable. Now let’s take a look at how a range of industries use this amazing technology.

1. Chemical industry: The backbone of modern manufacturing

In the chemical industry, Continuous Stirred Tank Bioreactors are employed to produce polymers, fine chemicals, and necessary pharmaceuticals. They are particularly preferred for reactions that require one to monitor the temperature, speed of mixing and time of mixing. Focus areas include:

- Polymers and plastics: CSTRs facilitate polymerization reactions, producing substances such as polyethylene, polypropylene, and others. The steady-state conditions are useful for the achievement of the relevant molecular weights, which are very important for the product.

- Pharmaceuticals: Most life-saving medicines, including antibiotics, are produced using CSTRs. The reversibility of reactions makes CSTRs suitable for complex pharmaceutical processes.

Key benefits:

- Optimized yields: Continuous operation of the machines means little downtime, boosting productivity.

- Energy efficiency: Research indicates that CSTRs can lower energy consumption by up to 70% as compared to batch processes.

- Cost reduction: Maintaining a steady-state during operations also reduces material losses and process disturbances.

1. Bioremediation and waste treatment: Cleaning the environment

Continuous Stirred Tank Bioreactor is effectively employed in bioremediation to treat wastewater containing a high level of hydrocarbon. Through successful cultivation of the required microbial cultures, the CSTR assimilates pollutants continuously. This is a critical process for industries aiming to lessen their influence on the environment.

How does it work? Waste and nutrients are continuously added to the reactor. Then, the microbes reduce the dangerous substances into harmless products such as water and carbon dioxide.

According to a journal, a CSTR bioreactor was applied in the treatment of refinery wastewater. Microbial cultures cleared more than 90% of hydrocarbon pollutants in the process.

Why CSTRs excel in waste treatment:

- Even distribution of microorganisms and nutrients is guaranteed by uniform mixing.

- Constant operation reduces idle time and avoids congestion.

2. Food and beverage industry: A recipe for efficiency

Continuous Stirred Tank Bioreactors are essential to the manufacturing of food and beverages — from beer brewing to the manufacture of enzymes. In comparison to the conical fermenters that are often used in batch fermentation, CSTRs run continuously, improving performance and ensuring high-quality standards. Core application areas include:

- Alcohol production: Crisp and rich beer, wine, and spirits result from the accurate control that CSTRs provide. The ability to maintain the right temperature, acidity level, and other fermentation conditions helps to retain uniformity in taste.

- Enzyme synthesis: Microbial enzymes employed in food processing are generated using CSTRs because they maintain microbial cultures for long periods of time.

Advantages over batch systems:

- Production capacity is increased through continuous operation.

- Uniform mixing ensures even fermentation, avoiding concentration gradients.

3. Biofuel production: Powering the future

Continuous Stirred Tank Bioreactors are used in the clean energy industry. As an example, anaerobic digestion is used to produce biogas. Anaerobic bacteria in the reactor decompose organic materials, such as municipal or agricultural waste. The result? Methane-rich biogas.

Prolonged mixing ensures constant microbial activities and optimal gas generation. Compared to conventional digesters, facilities that have adopted CSTR technology have achieved methane yield improvements of up to 20%.

Besides biogas, CSTRs are being tested in the production of algae-related biofuel. These biofuels are being considered a viable replacement for fossil fuels.

4. Research and development: From concept to scale

Processes generally begin in smaller CSTRs during research and development before being scaled up to industrial production. These single-use bioreactors or smaller stainless steel fermenter units are useful for verifying feasibility, optimizing conditions, and testing reaction kinetics.

Applications in R&D:

- Testing novel pharmaceutical drug fermentation techniques.

- Creating environmentally friendly chemical reaction processes.

- Investigating approaches in synthetic biology to improve output.

The scalability of the Continuous Stirred Tank Bioreactors means that successful lab experiments can smoothly shift to mass production with minimal adjustments.

5. Cosmetic and personal care industry

CSTRs are used to manufacture products such as lactic acid and bioactive compounds. These substances form the basis of skin-nourishing and skin-rejuvenating products.

For example, Continuous Stirred Tank Bioreactors facilitate the fermentation processes used in the production of collagen skin boosters. These skin boosters aid in increasing skin suppleness and minimizing wrinkles.

6. Agriculture

In agriculture, CSTRs are used for the production of biofertilizers and biopesticides. These result from microbial fermentations in which bacteria or fungi manufacture compounds that are useful in boosting soil health and managing pests. The system’s steady-state operation guarantees regular and consistent production of high-quality agricultural inputs and output, maintaining eco-friendliness and performance.

Example: Azotobacter-based biofertilizers produced in CSTRs enhance nitrogen fixation in soils, lowering the demand for artificial fertilizers.

7. Plastics and biodegradable polymers

CSTRs contribute to the manufacturing of biodegradable polymers. For instance, the conversion of sugar-containing feedstock to lactic acid. This acid is an important monomer in the production of polylactic acid (PLA). This application is on the rise due to the shift of industries toward eco-friendly materials.

8. Textile Industry

The enzymes that CSTRs produce are used in textile processes and treatments such as bio-polishing to enhance fabric smoothness. These enzymes provide a more environmentally friendly substitute for adverse substances.

9. Fine chemical synthesis

Continuous Stirred Tank Bioreactors are widely applied in food, cosmetics, and pharmaceutical industries for the preparation of high quality fine chemicals like artificial flavors, fragrances, and organic acids. Their ability to maintain stable reaction conditions provides reliable quality.

10. Aquaculture

In aquaculture, the algae and bacteria that are used to feed fish and other marine life are cultivated in CSTRs. By offering a regulated setting and high nutrient feedstock, these bioreactors significantly improve the sustainability of aquaculture techniques.

CSTR vs. Other Reactor Types

How are Continuous Stirred Tank Bioreactors unique from other reactor types like disposal bioreactors or PFRs (Plug Flow Reactors)? Explore!

- Consistency: Uniform mixing is critical for sustaining steady product standards.

- Scalability: CSTRs are versatile in growing from smaller research and development centers to large production centers.

- Cost-efficiency: Continuous operation has less downtime and consumes less energy than batch processes.

Advantages of using CSTRs

The Continuous Stirred Tank Bioreactors is one of the most effective and versatile reactors used in plenty of industrial and biological operations. Let’s look at its key advantages:

1. Uniform quality of products

Since the mixing is ongoing, the contents of the CSTR are uniformly distributed. This controls factors such as heat level, composition, and pH, ensuring each molecule of the end product is indistinguishable.

This consistency is important for processes such as drug manufacture.

2. Scalability from lab to industrial production

Scalability is one of CSTR’s most remarkable qualities. To scale production, the same concepts that are used in a tiny, single-use bioreactor for research and development can be easily transferred to a huge stainless steel fermenter. This flexibility helps cut down risks and expenses during the rollout of larger-scale business processes.

3. Cost efficiency

Continuous Stirred Tank Bioreactors are made to run continuously. This means that they are built to work for prolonged durations without an operational breakdown. This has led to energy savings of up to 70% when compared to batch processes in certain industries. Steady-state operations also eliminate the need for frequent changes, lowering operating costs.

4. Versatility across reactions

CSTRs may handle a variety of reaction types, such as solid-liquid reactions, as well as gaseous-liquid reactions. Because they have sturdy structures, they deal with tough processes such as fermenting enzymes for the production of food and synthesizing biodegradable plastics.

Limitations of CSTRs

Although Continuous Stirred Tank Bioreactors provide several benefits, but they also have a few disadvantages. The following are some of the disadvantages:

1. Non-ideal mixing

Although the design sustains consistency, some conditions may result in problems like dead space or short-circuiting. This is characterized by regions within the body of a fluid not mixing properly or exiting a reactor early. These events have the potential of compromising the quality of the developed products and decreasing the overall reaction yields.

2. Slow reactions or challenges with multi-phase systems

For reactions that take longer times to occur such as extremely slow chemical or biological reactions, Continuous Stirred Tank Bioreactors are less appropriate. Complexity can also arise from multi-phase processes such as immiscible liquids or solids, requiring additional design factors for efficient mixing.

3. Maintenance concerns

The Continuous Stirred Tank Bioreactors operate through constant stirring, exposing the impellers, seals, and bearings to wear and tear. Ongoing maintenance is essential in order to avoid mechanical failures that can add to the expenses of operating the machine.

Future Trends and Practical Uses of CSTRs

With new technology and developing fields driving their development, Continuous Stirred Tank Bioreactors appear to have a bright future. Here’s what’s on the horizon:

1. Bioengineering for sustainable manufacturing

As most industries switch to more sustainable processes, CSTRs are being employed to process biodegradable polymers, bio-derived chemicals, and other related sustainable materials. Microbial fermentation using CSTRs provides a cleaner alternative to petroleum-based production.

2. Uses in Bioengineering

Artificial biology uses genetically engineered microorganisms for the synthesis of valuable products such as biopharmaceuticals and specialty chemicals. Due to the high degree of control that is achievable within Continuous Stirred Tank Bioreactors, they are suitable for nurturing these modified organisms.

3. Carbon capture and utilization (CCU)

CSTRs are being incorporated into devices used for capturing and converting CO₂ into useful commodities including biofuels and organic acids. This not only leads to reduced greenhouse emissions but also the production of economic revenue outputs.

4. Hybrid systems

Subsequent Continuous Stirred Tank Bioreactors are expected to incorporate some characteristics of other types of reactors such as the plug flow or semi-batch systems to form new hybrid reactors that will leverage the merits of various systems.

Conclusion: Why CSTRs Matter

The Continuous Stirred Tank Bioreactors is not just a reactor. It’s an innovation powerhouse. Starting from purification of our wastewater to powering renewable energy and manufacturing of life-saving drugs, the applications of the CSTR are endless.

Whether in an industrial-grade stainless steel fermenter or a disposable bioreactor for short-term uses, this technology showcases the potential of good design.

Take Your Processes to the Next Level with Bailun’s Continuous Stirred Tank Bioreactors

Are you ready to optimize your processes and reach new levels of productivity? Here at Bailun Technology, we focus on providing Continuous Stirred Tank Bioreactors designed to meet the demand for current industry needs.

Whether you’re producing pharmaceuticals, biofuels, and fine chemicals, our fermenters provide the flexibility and productivity that are sought after for any process. Ready to upgrade? Reach out today and discover how our CSTR solutions can revolutionize your production process.