This article aims at providing an understanding of how a steam boiler operation is done to explain the network of systems that dictates the operation. Further, it will give a detailed analysis of the boiler types that can be purchased in the market to ensure that industries and even individual consumers can know the varieties they can access in the market.

Consequently, through studying the system of boilers and their classifications based on their construction and functions in the given paper, the readers are introduced to the importance and applicability of those vital elements incorporated in the contemporary engineering fields and applications.

What is a Steam Boiler?

A steam boiler is a closed vessel that transfers heat energy to water to produce steam with considerably high pressure. The produced steam is thus utilized in several industrial processes, generation of electricity, and the provision of heat. According to the steam boilers operation, they work on a very basic principle that heat is transferred to water in a controlled manner to produce steam.

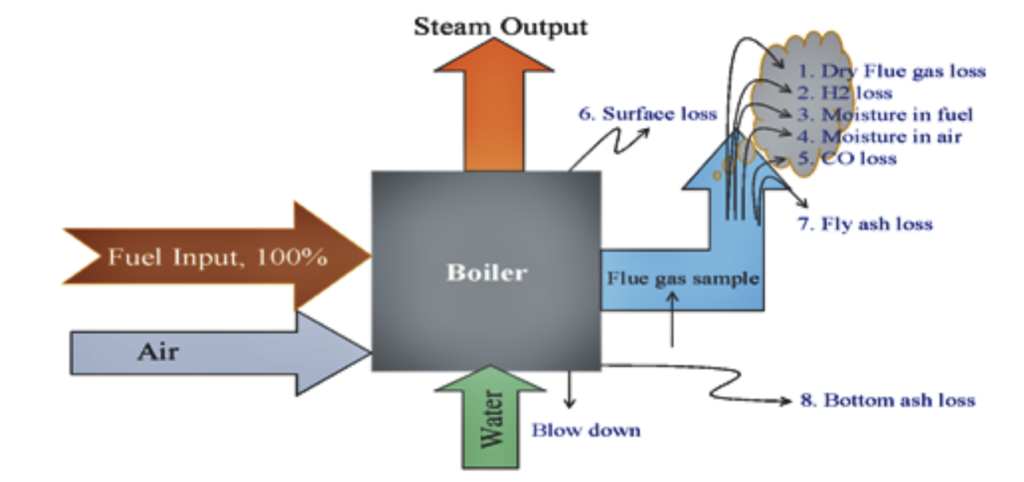

The basic process of operation of a steam boiler depends on the notion that when fuel is set on fire, it produces heat energy. This released heat energy is then transferred to water in the boiler where through a process, the water is heated to steam or hot water production. It means the effective conversion of energy is helpful in the efficient functioning of the boiler and the achievement of high thermal efficiency.

This effective heat exchange is the basis of steam boiler operation, underlining the importance of burners’ task. In fact, the operation of the steam boiler depends on the integration of the following processes which plays a very crucial role in using heat energy for generating steam or hot water.

Modes of Processing

Here, the steam boiler operation can be described as follows in terms of three fundamental modes of the process.

1. Fuel Combustion

- It starts with the burning of the fuel which includes coal, oil, gas or biomass in the furnace.

- The burning fuel makes a lot of heat which is in turn used to heat water in the boiler’s heat exchanger.

2. Heat Transfer to Water

- Heat generated in the furnace goes through the walls of the boiler as well as through the boiler tubes, heating up water inside the boiler.

- The water truly warms up and when it attains the boiling point, turns into steam.

3. Steam Generation and Expansion

- The heat produced in the furnace generates steam which accumulates pressure inside the boiler.

- The high-pressure steam is then allowed to expand through turbines, industrial equipment or heating system.

- The used steam may be condensed in the condenser and returned as feed-water for the circulation in the system.

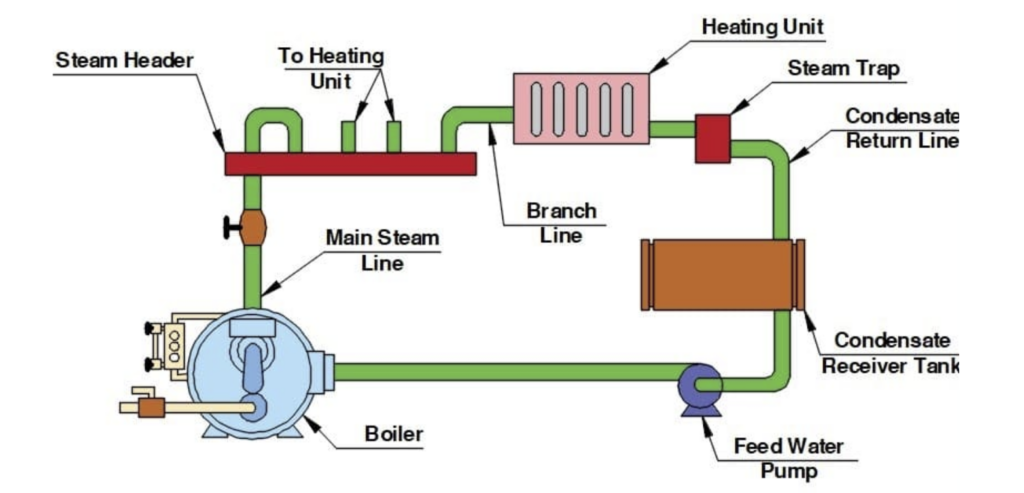

Components of a Steam Boiler System

Let us examine the system of this boiler and its main parts in order to comprehend it more easily.

- Furnace: An enclosure where fuel is burnt to produce heat or in other words the heart of a direct process furnace.

- Boiler Shell: The outer casing that houses water and steam.

- Heat Exchanger Tubes: The tubes where heat from the combustion gases is transferred to the water.

- Steam Drum: It is a vessel which is used to collect and store steam with the intention of delivering it forthwith.

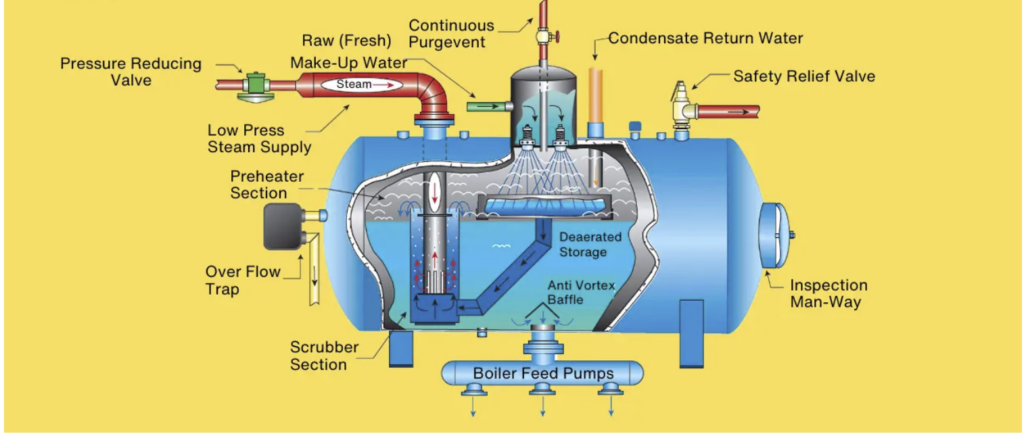

- Feedwater System: It is utilized for supplying fresh water to the boiler and to regulate pressure.

- Blowdown System: It is used for releasing the impurities and to maintain quality of water.

- Safety Valves and Controls: Ensure pressure and temperature stay within safe operating limits.

Types of Steam Boilers

There are several boiler types depending on the applications and working conditions such as:

1. Fire-Tube Boilers

- Them is transferred through pipes that are submerged in water.

- Suitable for low-pressure steam applications.

- Frequent in heating systems and small industries.

2. Water-Tube Boilers

- But, water flows through the tubes while the hot gases are on the outside of the tubes.

- Ideal for high-pressure and high-capacity operations.

- These are used in power plants and heavy industries and they are also known as bearing boxes.

3. Electric Boilers

- Replace combustion with electricity as the means of operation.

- Environmentally friendly, with zero emissions.

- Most suited for small scale use and research facilities only.

4. Waste Heat Boilers

- Waste heat from all industrial processes should be utilized to produce steam.

- Enhance the quality of energy used in processes while at the same time lowering the expenses in operations.

5. Modular Boilers

- This means that to satisfy a range of steam requirements, a number of small boilers are installed and used.

- More efficient and flexible than single large boilers.

Importance of Steam Boiler Efficiency

It is with regard to efficiency; this is one area of paramount importance to the steam boiler. A well-optimized boiler system ensures:

- The efficient management of energy sources for fuel consumption lowers operational costs while delivering major environmental impact benefits by decreasing both greenhouse gas production and total environmental harm.

- Every industry needs this reduced emissions footprint as part of its commitment to both combat global climate change and promote sustainable practices.

- The optimized fuel consumption and proper maintenance practices lead boilers to have longer operational lives which improves both efficiency and cost-effectiveness for industrial facilities.

- The combination of steady supply of steam and lowered fuel consumption and well-kept equipment systems enables critical industrial processes and boosts manufacturing efficiency while providing stable power supplies.

- Sustainable energy practices produce dual advantages of reduced fuel usage as well as lowered emissions with added benefits of longer boiler operation duration and dependable steam delivery which establish their essential role in industrial environmental stewardship and operational excellence.

Tips to Enhance Boiler Efficiency

Here are some tips to enhance steam boiler operation efficiency:

- Ensure that the insulation material used for the walls and roof is correctly installed to avoid heat loss.

- In this case, the best way to ensure that water does not cause scaling or corrode the equipment is to maintain water quality.

- The reaction controls that burn the fuel to the greatest extent possible must be enhanced.

- Conduct regular maintenance and inspections.

Common Problems in Steam Boilers

Problems that may be encountered in steam boilers are:

- Formation and Corrosion: Mineral deposits tend to lower the efficiency of heat transfer.

- Pressure Variations: Fluctuations of pressure in terms of expectation either positive or negative are not very good for performance.

- Leakages: Loss may occur through steam or water pipes and valves if they get spoilt.

- Overheating: This is the case because blood circulation is poor and this may lead to generation of heat.

Such issues need to be addressed and regularly checked so that they do not disrupt the steam boiler operation in the future.

Final Thoughts

Modern industrial facilities heavily depend on steam boilers operation as they function like primary delivery systems for steam needed to satisfy different operational requirements. Using operational knowledge about boiler mechanisms combined with an understanding of different systems of boiler y boiler types allow people to properly implement measures that strengthen business operations. The gained knowledge enables professionals to boost production capacity while maximizing operational efficiency while designing strategies that lower operational expenditure in business operations.

Our sophisticated system combined with advanced technological solutions delivers services that exceed your needs and operate with efficiency to deliver solutions that match your precise requirements. Our devotion to excellence allows us to deliver solutions that combine efficiency and operational suitability which results in optimal performance and productivity among your industrial operations. Contáctenos for more info!

Preguntas frecuentes

- What is the use of a steam boiler?

Steam boiler is employed for generating steam for various applications, generating power and for heating purposes.

- Can you explain the difference between the fire tube and water tube?

The fire tube boilers have the hot flue gases passing through the tubes which are surrounded by water and the water-tube boilers have the water inside the tubes while the outer surface of the tubes is exposed to the hot gases.

- What are the ways that can be taken to increase the efficiency of the boiler?

Some of the methods that can be used for improving efficiency include; frequent maintenance checks, constantly treating the water used in the plant, improving efficiency of the combustion process and insulating the plant among others.

- What kind of fuels are used in the steam boilers?

Some of the frequently used fuels are coal, natural gas, oil, bio fuels and electricity.

- What can be deduced about the frequency of inspection of a steam boiler?

It is recommended that boilers should be inspected at least once a year in order to guarantee efficient operation and safe working conditions.