In this article, we’ll take a closer look at the concept of biogenesis, explore its biological underpinnings, and discuss how bioreactors enable the controlled manipulation of this process to meet industrial demands.

What is Biogenesis? A Look at Biogenesis Definition

Biogenesis is a biological term that describes how organisms or cells are formed from other organisms or cells. It is the term first introduced by Louis Pasteur in the 19th century. The definition of biogenesis can be broken down into two main components: the origin of life and the reproduction of life.

- The origin of life aspect of biogenesis refers to the idea that life cannot arise spontaneously from non-living matter.

- The reproduction of life aspect of biogenesis refers to the idea that living organisms produce offspring that are similar to themselves.

In modern biotechnology, biogenesis describes the process by which cells multiply, divide and generate proteins, enzymes or biofuels. These reactions play an important role in applications ranging from vaccines to bioengineering clean energy.

Key Biological Processes in Biogenesis

Biogenesis involves several biological processes that are all important for generating bioproducts. The most significant of these are:

- Protein Synthesis:Proteins are the building blocks of life and are at the heart of fields such as therapeutic drug discovery and vaccine construction. These proteins are stimulated by biogenesis, which promotes transcription and translation within cells. Optimized cell culture conditions allow the successful production of quality proteins.

- Enzyme Manufacturing:Enzymes are the catalysts of biochemical reactions which play a critical role in industrial and pharmaceutical industries. Biogenesis makes enzymes accessible for mass production by producing custom microbes or cell lines in controlled conditions.

- Biofuel Production: Renewable energies such as biofuels require biogenesis. Algae or bacteria convert substrates into biofuel via photosynthesis or metabolic processes, providing a renewable alternative to fossil fuels.

What Are the Important Factors that Impact Bioproduct Yield in Biogenesis?

The goal of high-quality biogenesis requires accurate regulation of a variety of factors that affect cell growth, metabolism and yield. These factors include:

1). Cell Growth & Proliferation

Bioproduction of bioproduct and subsequent yield is greatly influenced by the proliferation and growth of cells. The process of healthy cell division is required for biogenesis to proceed at desired rates. And that means maintaining the right conditions — nutrients, toxins that prevent growth, etc. In other words, when the cells reproduce, they become more efficient at producing a protein or vaccine. To maximize the overall yield, a major goal is to grow the cells to their full potential in tightly monitored bioreactor conditions.

2). Nutrient Availability

One of the most critical biogenesis considerations is also the concentration of nutrients in the bioreactor. Cells require an endless supply of amino acids, glucose, vitamins and other building blocks and nutrients to thrive and to synthesize. Insufficient nutrients can hinder cell growth and bioproduct production. The nutrients management of bioreactors allow the delivery of growth media so cells are never depleted of nutrients to effectively fuel biogenesis.

3). Environmental Control

The mechanical condition of bioreactor has to be managed precisely to achieve the ideal biogenesis. Dissolved oxygen levels, pH, temperature and agitation are needed to be adjusted or moderated to create the conditions needed for growth and product production.

- Temperature: Various cell types require various temperature ranges to flourish. However, these deviances slow down the metabolism of cells and reduce yield.

- Oxygen: You need adequate oxygen for aerobic respiration and cellular energy production. Lack of oxygen leads to cell death and reduced yield.

- pH:The pH of the conditions inside the bioreactor impacts metabolism and enzyme activity. You have to be able to precisely control it, in order to keep biosynthesis at optimal levels.

Biogenesis and the Function of Bioreactors

A bioreactor is a device or container that’s used to grow cells or microbes at their optimal growth rates. In industrial biogenesis, bioreactors need exact measurements of growth and yield. — Bioreactors also regulate temperature, pH, oxygen, and agitation. They’re usually well-monitored to ensure conditions are ripe for biogenesis.

Among the most important advantages of bioreactors are:

- Temp Control: Temperature controlled heating and cooling to individual cell types.

- Aeration: Oxygen provision for aerobic living systems.

- Agitation: Mixing or shaking to mix nutrients and gases into the medium.

- Real-Time Monitoring: Sensors monitor chemistry such as pH, dissolved oxygen, and nutrients, allowing adjustments to keep things in perfect shape.

Top Bioreactors for Biogenesis

There are several types of bioreactors for both industrial and research purposes, varying in scale, application and process. The following is an extended list of the main types, their features and uses.

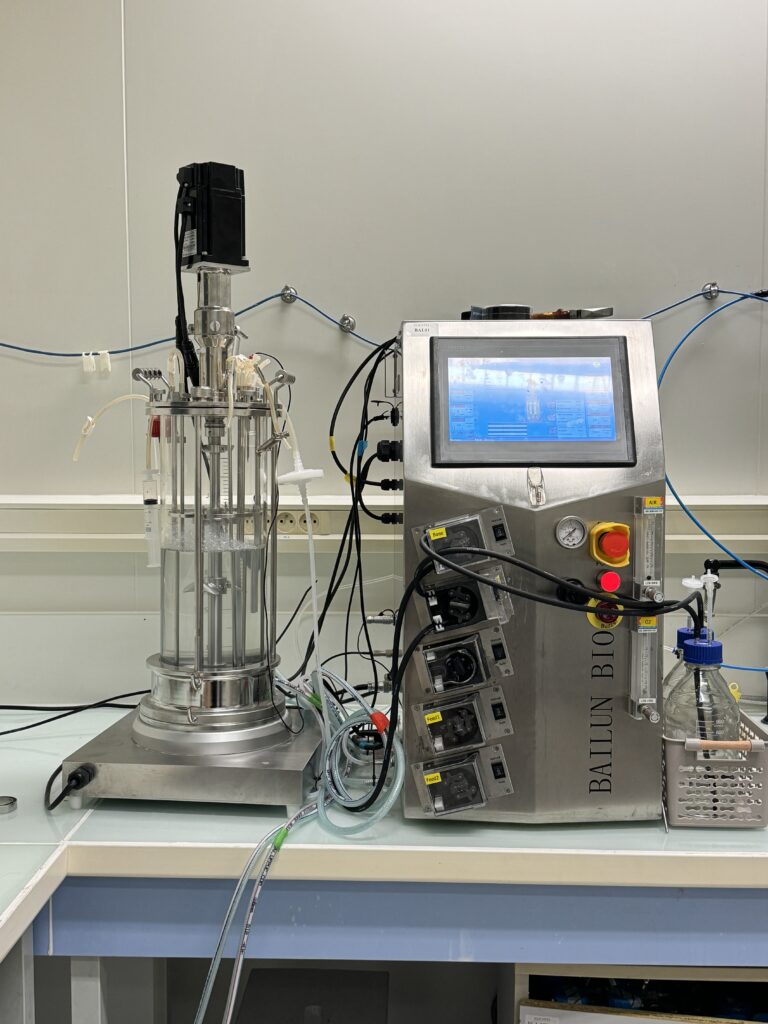

1). Lab Bioreactors

What Is It

Lab bioreactors are tiny, lightweight research and development platforms. They provide a laboratory environment to explore and modify biological behaviour on a molecular level, usually early in life. These bioreactors are critical for understanding microbial behaviour, enzymes and biosynthetic processes, and are therefore indispensable in laboratories.

Features

- Glass or acrylic transparent display.

- Pro level pH, temperature, aeration, agitation controls.

- Kleine Menge (mililitres to few liters).

- Built for different lifeforms and bioprocesses.

Roles in Biogenesis

Lab bioreactors are mere research and process-development devices. They are used by scientists to explore biosynthetic pathways, validate substrates and determine the optimal environment for microbes or cells to grow. They are used for proto-drug design, enzyme production, and metabolite manufacture. In biogenesis, they offer a means of identifying processes that could eventually be industrialised – hence innovation and efficiency at the earliest levels.

2). Parallel Bioreactors

What Is It

Parallel bioreactors are mini machines that operate simultaneously. They are perfect for comparative analyses of variables. Bioprocess optimisation by such a bioreactor can be done quickly, and the outcomes are repeatable and reusable across systems.

Features

- Independent control for each unit

- Automated system configuration and data acquisition in real time.

- Stable structure with reproducible effects between experiments.

- Compact design for laboratory space.

Role in Biogenesis

Parallel bioreactors are extremely useful in R&D, process and strain optimization. They allow researchers to experiment on many different parameters, including nutrient concentration or temperature, in one session. This is important in biogenesis to identifying the best conditions to produce a biological product you’re interested in (for example, proteins, enzymes or metabolites). Parallel bioreactors accelerate process development, thereby reducing the time and cost of testing over and over.

3). Pilot Bioreactors

What Is It

Pilot bioreactors serve as an intermediate solution between small scale lab-scale and large-scale production. With these bioreactors, you can test and hone your bioprocess before scaling up to larger volumes with more features. They enable scalability and reproducibility.

Features

- 10L to 1000L volumes.

- Durable construction for long-term operation.

- Fully automated monitoring platforms for precise environment management.

- Scalable to mimic industrial conditions.

Role in Biogenesis

Pilot bioreactors are used for process validation and scale-up studies. They can help transition small experiments to larger-scale manufacturing in biogenesis by emulating industrial processes at a microlevel. They make sure biosynthetic processes and microbial or cell cultures behave the same at a larger scale. The pilot bioreactors are useful for prototyping drugs, enzymes or biofuels before full scale production can take place so businesses can perfect the production flow.

4). Industrial Bioreactors

What Is It

Industrial bioreactors are full-scale systems for commercial production. They can accommodate from a thousand to hundreds of thousands of litres and are optimised for high productivity and low cost production. They support various biogenesis processes from pharmaceutical manufacturing to biofuel production.

Features

- Large scale production systems in high volumes.

- Integrated process control systems for process monitoring and control in real time.

- Energy efficient design for sustainability.

- Advanced mixing and aeration for consistency.

Role in Biogenesis

Commercial biogenesis applications rely on industrial bioreactors. They allow for the mass production of important bioproducts such as vaccines, biologics, enzymes and biofuels. They aim to increase yields at the lowest cost, and are therefore necessary to scale-up lab-based biogenesis processes. Industrial bioreactors also provide regulatory compliance and stable products. In biogenesis, they facilitate the widespread application of biosynthetic pathways, enabling innovation and the fulfillment of the worldwide demand for biological products.

5). Solid-State Bioreactors

What Is It

For processes that use solid substrates rather than liquids, solid-state bioreactors are suitable. They work well with agricultural residues or other solid waste, so they’re also ideal for sustainable, environmentally friendly biogenesis.

Features

- Low water consumption, lower cost of operation.

- Setups for solid substrates, trays or packed beds.

- Aeration and moisture control.

- Compatible with multiple microbial strains depending on application.

Role in Biogenesis

Enzymes, organic acids and specialty chemicals are made using solid-state bioreactors, by solid-state fermentation. They permit agricultural waste, waste valorisation and biodegradability. For instance, cellulases and proteases are made using solid-state bioreactors in biofuels, textiles and paper. They can preserve the best state on the solids, high efficiency and productivity, progressive biogenesis, and sustainable.

What are the Major Applications of Biogenesis?

Here are a few of the major areas in which biogenesis is being useful:

1. Vaccine Production

Biogenesis is the backbone of vaccine production, especially for viral vaccines. It involves growing mammalian cells – Chinese hamster ovary (CHO) cells or any cell line – in bioreactors. They are designed or infected to generate virus proteins or virus wholes, and these cells are culled and used in vaccines.

Key Benefits

- Fast and reliable production: High capacity, uniform yields, with high efficiency and reliability due to the fact that our bioreactors provide the perfect environment for the growth of cells (temperature, pH, and oxygen).

- Scalability:The new biogenesis technologies can mass-produce to satisfy the demand worldwide for vaccines, especially during pandemics such as COVID-19.

- Risk of contamination: Because of the safe atmosphere of bioreactors, the potential for contamination of vaccines is minimised.

- Applications: Biogenesis has been put to work in flu, COVID-19, hepatitis and other viral infections, all of which have had dramatic health benefits around the world.

2. Therapeutic Protein Synthesis

Biogenesis is essential for the synthesis of therapeutic proteins such as insulin, growth factors and monoclonal antibodies. Once the host cells (bacterial, yeast or mammalian) are introduced with recombinant DNA, the cells can be programmed to make the protein of interest, then the proteins are isolated and purified. These proteins are essential for diseases such as diabetes, cancer and autoimmune disorders.

Key Benefits

- Increases protein yield: Limiting cell growth and improving the conditions of growth lead to increased protein yield from bioreactors.

- Scalability:Biogenesis methods enable mass production of therapeutic proteins for global distribution.

- High quality and purity:High-tech purification techniques ensure therapeutic proteins are of a very high quality medical standards.

- Applications: Antimicrobial proteins are the stuff of science, and help to combat medical problems from diabetes (with insulin deficiency), cancers (with tumour-targeted therapy) and autoimmune disease.

3. Enzyme Production

The production of enzymes for all sorts of industries from food production to pharmaceuticals relies on biogenesis. Embryos like bacteria and fungi are grown in bioreactors that yield enzymes, and they’re collected and distilled for industrial or therapeutic purposes.

Key Benefits

- High yield:Fermentation process optimized to achieve high enzyme yield in a short period of time.

- Efficient:In the bioreactor, enzymes are cheaper to produce on a large scale, and therefore affordable.

- Applications:Enzymes such as proteases and lipases help remove stains and clean it better.

- Examples: Hydrolysers of starch in food processing.

4. Biofuel Production

Through biogenesis, renewable fuels like ethanol, biodiesel and biogas can be made from organic waste such as agricultural residues, algae and waste. Microbes ferment and enzymes metabolise these raw materials into biofuels.

Key Benefits

- Energy source – renewables:Biofuels are alternatives to fossil fuels and are sustainable in terms of energy.

- Industrial Biofuels: Large scale Bioreactors can be made to generate industrial biofuels.

- Non-computational: It minimizes greenhouse gases thereby avoiding climate change.

- Applications: Ethanol as a biofuel in petrol, Biodiesel for diesel engines, Renewable Biogas for electricity and heating.

5. Food and Beverage Industry

Food and beverages industries depend on biogenesis (fermentation) to make many products that taste, feel and retain better. Cultured microbes (bacteria, yeast) are used to make finished goods from raw materials.

Key Benefits

- Stability: Proper fermentation will guarantee consistency in flavour and texture from batch to batch.

- Large-scale production: Biogenesis process is suitable for manufacturing large quantities of food and beverage for consumption.

- Better shelf life: Fermentation makes the product last longer naturally and with fewer artificial preservatives.

- Applications: Yogurt and cheese production (Dairy), Beer, wine, and kombucha (Beverages), Soy sauce and vinegar (Condiments)

Conclusion: Unlock the Power of Biogenesis with BaiLun Biotechnology

Biogenesis and bioreactors, in other words, are changing the game in multiple industries. Utilizing natural processes in organisms and tuning them to the best use of the laboratory — biogenesis can create valuable bioproducts. And innovation is our business, so BaiLun Biotechnology Co., Ltd provides cutting-edge bioreactor technology for your business success in biopharmaceutical production, enzyme development, and more.

If you partner with BaiLun, you’ll be able to provide the highest level of safety and compliance, and drive more productivity and quality in your products. Contact us today to find out more or to book a consultation.