Let’s dive into the critical role of microorganisms in fermentation and how the proper equipment like bioreactor fermenters make the process as efficient as possible.

What is Fermentation?

The biochemical process in which microorganisms, such as bacteria, yeast and fungus, break down organic substances, usually sugars, to other compounds such as alcohols, acids and gases is known as “fermentation”. This process occurs without oxygen (anaerobic fermentation) or with oxygen (aerobic fermentation).

Essential compounds are produced cost-effectively and sustainably, making fermentation bioreactor an important process in many different industries with high throughput.

What makes fermentation so important?

- It helps in producing a diversity of products such as food, beverages, biofuels and pharmaceuticals.

- The technique is green and less energy-consuming than alternative production processes.

Role of Microorganisms in Fermentation

The unsung heroes of the fermentation bioreactor process are microorganisms. They have given us some of the world’s most popular foods, drinks and biotechnological products. Several types of microorganisms play pivotal roles in fermentation:

1. Yeasts

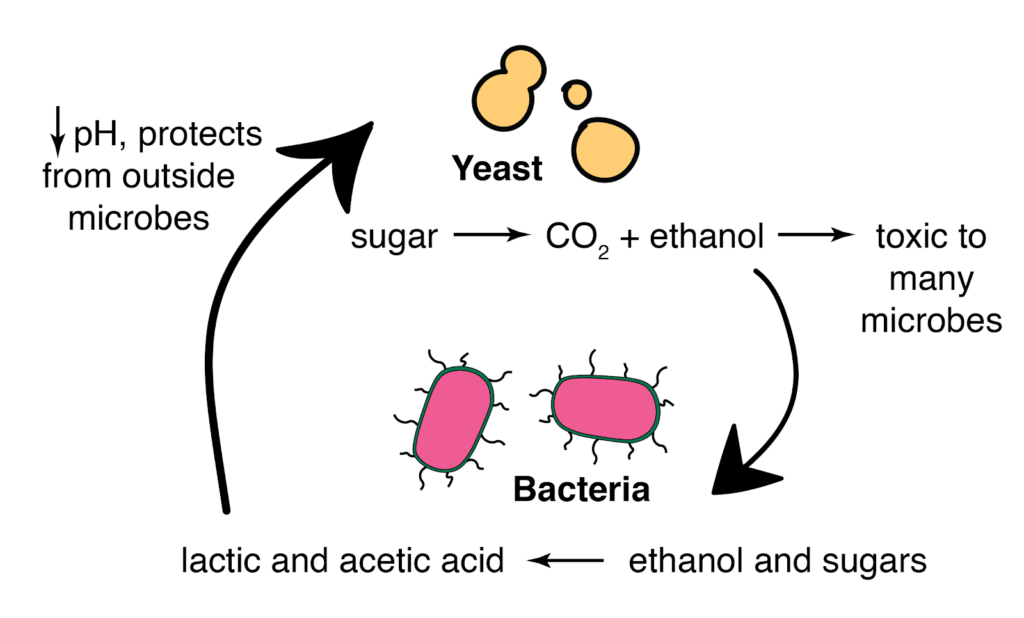

Baker’s yeast, commonly known as Saccharomyces cerevisiae, is one of the most commonly employed microorganisms of fermentation. Its role is to ferment sugars into alcohol and carbon dioxide. This yeast is essential in:

- Brewing beer

- Making wine

- Baking bread

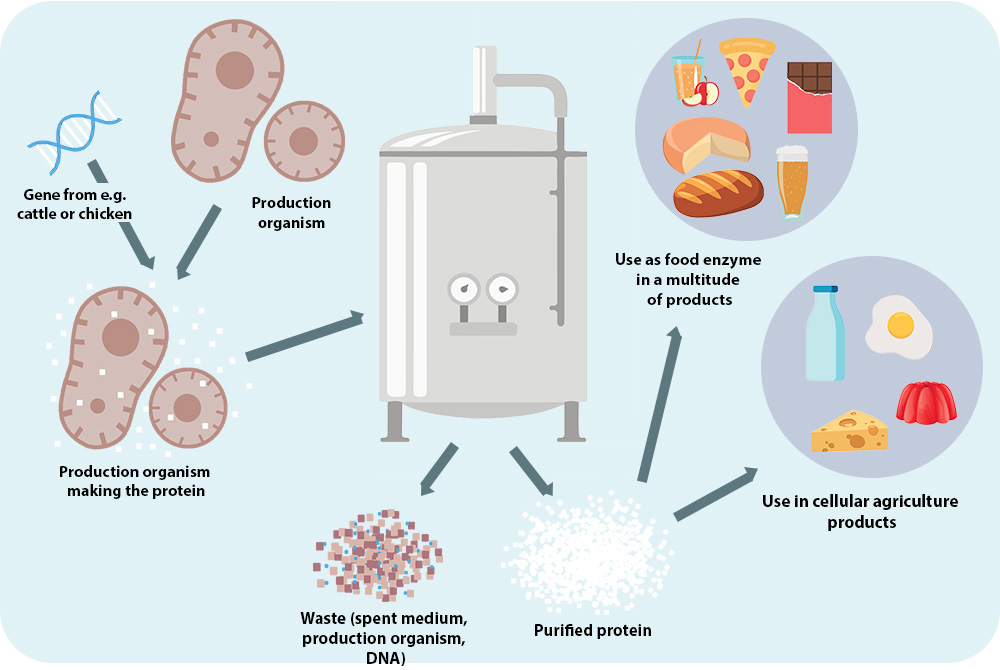

Despite this, another type of yeast, Pichia pastoris, is also widely used in the production of recombinant proteins and enzymes, thus making it a central player in the biotechnology and pharmaceutical industries.

2. Bacteria

Lactic acid bacteria (LAB) such as Lactobacillus and Streptococcus species are essential to the production of fermented dairy products, pickles and other probiotic foods. Using LAB, the transformation of sugars into lactic acid improves the shelf life and flavour of food products. They are used in:

- Yogurt production

- Cheese production

- Other fermented vegetables (such as kimchi and pickles)

Another group of bacteria, Clostridium species, also produce solvents like acetone and butanol, as well as biofuels

3. Molds

Aspergillus Niger, a mold, is commonly used to produce industrial enzymes and citric acid. This is particularly important for:

- Fermentation of fruits

- As a production of citric acid (widely used in the food industry as a preservative)

- Tempeh (as well as fermented soy products in general) is produced using Rhizopus species.

What is Bioreactor Fermenter?

A fermenter bioreactor is a bioreactor vessel used to perform fermentation under controlled conditions. It furnishes an appropriate environment for microorganisms to grow and metabolize substrates to the desired products. In particular, these systems are essential for scaling fermentation bioreactor processes in the industrial context.

Features of Bioreactor Fermenter

Below are some of the important features of bioreactor fermenter:

- Precise Control:The growth of microorganisms is regulated under a bioreactor fermenter more accurately than temperature, pH, oxygen, and agitation levels.

- Scalability:Bioreactors can be scaled up for production demands from small laboratory setups to large industrial applications.

- Sterility:The bioreactor fermenter is guaranteed to be sterile to prevent contamination and ensure that the cultures of microorganisms are the purest.

If you’re considering upgrading your fermentation processes, this type of bioreactor fermenter is a must-have for industries requiring controlled environments and higher scalability.

Applications of Bioreactor Fermentation

The applications for bioreactor fermentation in food production, pharmaceuticals, biofuels and renewable energy markets are vast.

1. Food and Beverage Industry

- Beer and Wine Production: A key yeast function is fermenting sugars to make alcohol, such as Saccharomyces cerevisiae, which is used in brewing and winemaking.

- Dairy Products:Lactobacillus bacteria are used to manufacture yoghurt and cheese to produce better flavor & texture.

2. Pharmaceutical Industry

- Antibiotics:The fermentation of Penicillium chrysogenum in which the Penicillin is produced is in a bioreactor fermenter.

- Vaccines:The use of a bioreactor fermenter supports microbial culture production for vaccine development.

3. Renewable Energy

- Bioethanol Production:Saccharomyces cerevisiae also uses it in the fermentation of sugars to make ethanol, a key biofuel.

- Biogas Production: Anaerobic bacteria located in bioreactors convert organic waste into biogas, a renewable energy.

How to Choose the Right Bioreactor Fermenter

To maximize the fermentation efficiency, the best fermenter bioreactor needs to be found. Here’s how to choose the best option:

· Scale of Production

Are you adding scale to your fermentation process? The size of your bioreactor will depend on the volume of the product you are going to produce. On a small scale, fermenters are built for laboratory purposes and the scale large-scale fermenters are designed for industrial purposes.

· Automation Features

The properties of modern bioreactor fermenter in which the measuring of parameters such as temperature, pH, and oxygen concentration is automated so advanced. This guarantees consistency keeping away a risk of human error.

· Material Construction

Correct material used in bioreactor fermenters is vital for durability and sterility. Stainless steel used is commonly stainless steel, because, stainless steel is resistant to corrosion as well as very easy to clean, whereas glass is being used in laboratory scale fermenters.

· Cost-Effectiveness

Do you need a low-cost solution? By improving bioreactor fermentation efficiency, bioreactor fermenter product yield, etc., long-term operational cost benefits can be brought in through investment in high-quality bioreactor fermenters.

When it comes to reliable, high-performance bioreactor fermenter, if you need products that meet your fermenting requirements, why not check out bioreactor fermenters of BaiLun?

Innovations in Bioreactor Fermentation

As biotechnology continues to evolve, several innovations are enhancing bioreactor fermentation processes:

- Genetically Modified Microorganisms:Genetic tailoring of microorganisms can increase fermentation process yields or produce novel compounds, improving the microorganism’s efficiency during fermentation.

- Sustainability:Fermentation is becoming more sustainable and environmentally friendly thanks to the development of alternative feedstocks such as waste products or algae.

- 3D Printing in Bioreactors:Built with 3D printing, bioreactors are customizable for each fermentation process, which means that they are a flexible choice for many industries.

Are you using the latest fermentation technologies? Being at the top of the curve means your business might hold competitive advantages in the market.

Conclusion

Biotechnology is a fermentation driven by microorganisms such as yeasts, bacteria or molds. This process can be enhanced using bioreactor fermenter which have precise control of environmental conditions and increase scalability. For the food, pharmaceutical or biofuel industry, bioreactor fermentation is vital for optimizing the production processes, but also for ensuring constant product quality.

Want to advance your fermentation processes one step further? Find out about effective, high-quality bioreactor fermenters which will help to improve your operations and maintain your competitive position in the rapidly developing biotechnology industry.

Contact BaiLun Bio, the best bioreactor fermenter solutions based on your needs.

FAQs

- Which microorganisms are the most common to be used in fermentation?

The most commonly used microorganisms include Saccharomyces cerevisiae (yeast), the bacteria Lactobacillus, and the mold Aspergillus Niger.

- How does a bioreactor improve the fermentation process?

The environmental conditions such as temperature and pH used in the bioreactor fermenter would be maintained such that microbial growth and the yield of the product are maximized.

- What types of industries use bioreactor fermentation?

Food and beverage production, pharmaceuticals, biofuels and renewable energy industries all use bioreactor fermentation.