Clinical manifestations are mainly characterized by closed jaws, systemic muscle rigidity, and paroxysmal spasms. Severe patients can experience asphyxia, laryngeal spasms, lung infections, organ failure, etc., posing a fatal threat to their life and health.

破伤风芽孢在自然环境中广泛存在,人类一般对破伤风没有天然免疫力,因此需要人工免疫,使机体对破伤风毒素产生免疫力。方法有主动免疫和被动免疫两种,接种破伤风疫苗属于主动免疫。

破伤风疫苗的主要成分是破伤风类毒素(TT),是由减毒的破伤风外毒素制成。破伤风的主动免疫是将破伤风类毒素接种到人体内,使人体产生针对破伤风毒素的抗体,从而获得免疫力。

疫苗分类

目前,我国预防破伤风的疫苗有以下五种:

- 吸附脱细胞百日咳联合疫苗(DTaP):由脱细胞百日咳疫苗原液(共纯化工艺)、白喉类毒素原液、破伤风类毒素原液添加氢氧化铝佐剂制成。用于预防百日咳、白喉、破伤风。

- DTaP Hib:DTaP Hib疫苗主要成分为DTaP联合疫苗(共纯化工艺)和流感嗜血杆菌联合疫苗。用于预防百日咳、白喉、破伤风以及乙型流感嗜血杆菌引起的侵袭性疾病。

- 吸附无细胞百日咳疫苗灭活脊髓灰质炎和乙型流感嗜血杆菌(DTaP IPV/Hib)联合疫苗:由吸附于氢氧化铝上的白喉类毒素、破伤风类毒素、两种纯化百日咳抗原(PT和FHA)、三种脊髓灰质炎病毒和乙型流感嗜血杆菌联合疫苗组成。用于预防百日咳、白喉、破伤风、脊髓灰质炎、乙型流感嗜血杆菌引起的侵袭性感染。

- 吸附白喉破伤风联合疫苗(DT):由白喉类毒素原液和破伤风类毒素原液添加氢氧化铝佐剂制成,用于已全程接种吸附百日咳、白喉、破伤风联合疫苗的儿童增强对白喉、破伤风的免疫力。

- 吸附破伤风疫苗是将破伤风梭菌在适宜的培养基中培养,产生毒素,经甲醛脱毒精制,再加入氢氧化铝佐剂而成,用于预防破伤风。

其中DTaP、DT为免疫计划疫苗,DTaP Hib、DTaP IPV//Hib、吸附破伤风疫苗为非免疫计划疫苗。

疫苗流程

- 菌株活化(国内采用的生产菌株为L58)

- 为了培养毒素的生产,需要采用培养槽深层培养,还必须通过通风排出硫化氢和二氧化碳)

- 甲醛加热解毒(目前采用的方法是0.36%甲醛pH中性,37℃解毒30天)

- 浓缩精制(超滤浓缩、硫酸沉淀)

- 除菌过滤(经0.22um微孔膜过滤去除细菌细胞)

- 精制破伤风毒素的吸附(用气态氧化铝吸附)

百仑破伤风疫苗工艺流程

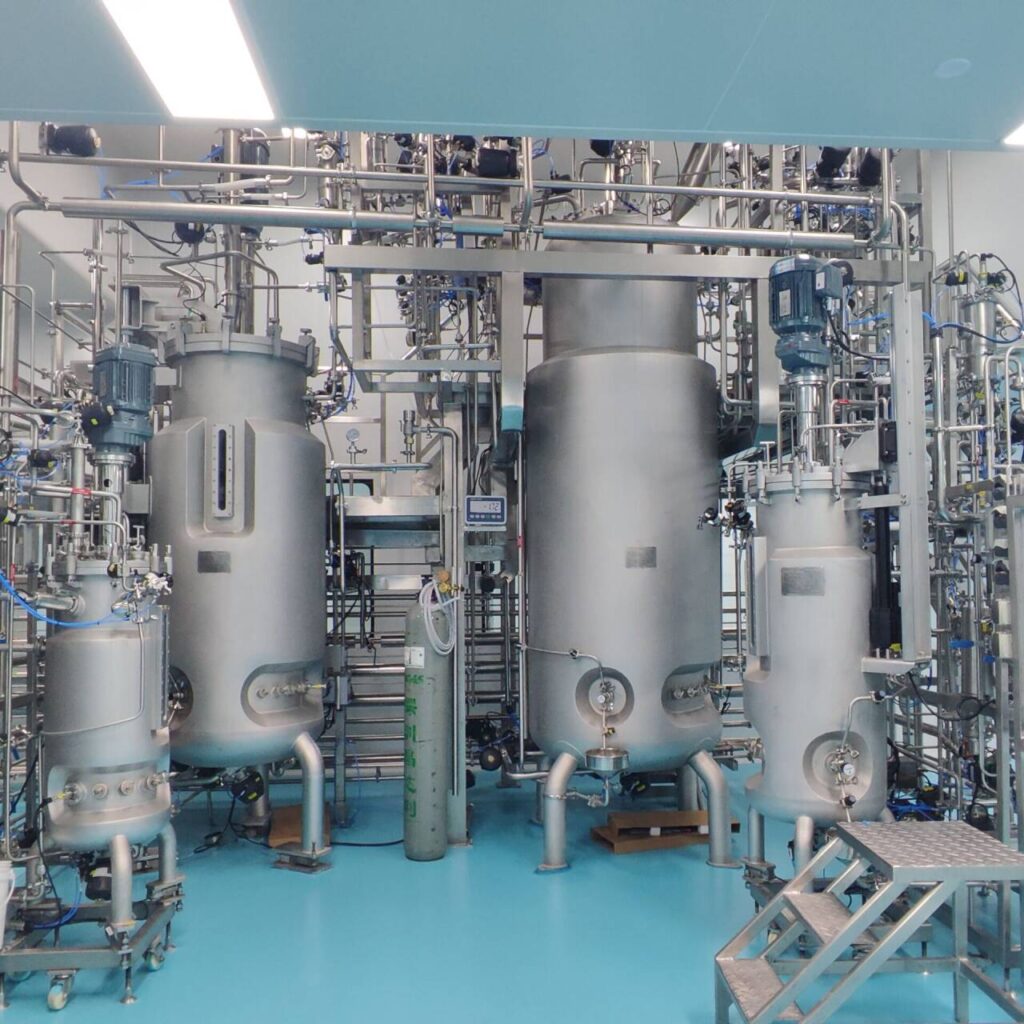

发酵生物反应器完美的密封设计,自动化的CIP、SIP,为高致病性毒素的生产提供了安全保障。发酵生物反应器独特的废气处理装置,有效去除有害气体,在保证生物安全的同时,保护了环境。

白仑酵素生物反应器 破伤风培养系统

Fermentation bioreactor are the main equipment for the production of tetanus vaccines.Bailun’s fermentation bioreactors are available in a variety of models and specifications to meet customers’ various production requirements.The height-to-diameter ratio of Balun’s fermentation bioreactor is 2:1, which is suitable for the cultivation of Clostridium tetanus.The surface ventilation design of the fermentation bioreactor is equipped with AIR automatic flow regulation.

关于百伦

百伦在各类发酵生物反应器制造方面拥有丰富的经验,拥有一批生物反应、发酵工艺、机械制造、自动化控制等领域的专家团队,科研技术水平始终走在国内乃至国际前列,为您提供舒适、放心、安心的产品体验。

The external components of the biological fermentation bioreactor should adhere to three conveniences, namely easy installation and disassembly, easy cleaning and sterilization, and easy operation and maintenance, and be able to withstand high-pressure steam sterilization;The biological fermentation bioreactor involves active substances during the cultivation process, so it must comply with biological safety standards. It should not only prevent all external microbial contamination, but also prevent the cultivation substances in the fermentation bioreactor from polluting the surrounding environment.

Therefore, the biological fermentation bioreactor should be a system device with good sealing performance, and its venting and discharge of gases and liquids inside the fermentation bioreactor need to be filtered to remove active substances;The biological fermentation bioreactor should have excellent mass/heat transfer efficiency and excellent material mixing performance to provide the optimal growth temperature of the culture.

To ensure that the fermentation bioreactor is sterile, it is very important to have a reasonable structural design of the fermentation bioreactor equipment and to actively introduce and absorb advanced technology.Bailun adheres to the principle that every detail embodies the principle of customer consideration, and continuously carries out technological innovation. The vaccine fermentation bioreactor product equipment components produced use standard parts, and the key accessories are basically consistent with European products.

At the same time, the pipelines are optimized. It facilitates maintenance and upkeep during operation and reduces customers’ usage costs. Safety, simplicity, precision, reliability and durability are the performance of its products. With the continuous advancement of technology, vaccine fermentation bioreactor products will also begin to move towards full automation, and fully automatic program sterilization will become a trend.

联系我们:

地址:6848# 上海市嘉定区留香路

联系人: 麦迪

邮箱:sales@fermentertech.com

电话:+86-134-7276-8163(WhatsApp)

网址:https://bioreactortech.com/